By Miguel Guerra, BI Lead

The Traditional BI Mindset: A Costly Waiting Game

For years, BI teams focused on answering questions like, “What happened last quarter?” Dashboards were static, KPIs took weeks to compile, and decision-making arrived too late to prevent disruption.

In aviation, where systems are fragmented across flight operations, maintenance, logistics, order management, finance, and ground handling, this delay translated into costly operational paradoxes: unexpected delays, missing parts, and inefficient crew scheduling.

The Inflection Point: Intelligence Meets Action

We’re now crossing an important threshold. AI is no longer about describing the past; it’s about anticipating and acting on the future:

- Predictive models can forecast part failures, weather-related delays, or crew absences.

- Natural language interfaces allow leaders to query complex data pipelines without writing a single line of code (e.g., “What is the engine failure risk in the next 72 hours for A320s?”).

- Embedded AI/ML triggers reprogramming, logistics alerts, and automatic planning, reducing the need for human intervention.

From my own experience leading ML deployments, reaching this point requires more than strong models. It requires agile, well-governed infrastructure that enables:

- Model monitoring and version control

- Rollback mechanisms

- Business-aligned metrics (e.g., inventory strategy, product positioning, etc)

This engineering discipline not only mitigates risk but also accelerates return on investment.

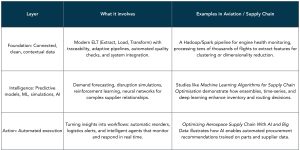

From Data to Automation

Capturing true value from AI/ML requires an architecture built on interconnected layers:

AMP Use Cases Driving AI in Aviation

Forecasting Model on Fabric

At AMP, we’ve seen that the true advantage lies not in isolated models but in orchestrating them within business processes on that scale. Some key examples:

Part Number Forecasting

Our machine learning models forecast future demand for aircraft parts across maintenance and airline operations. By combining planning, operational, and transactional data, we’re working on improving inventory precision, reducing procurement costs, and strengthening supply chain resilience.

Intelligent Process Agents

We’re also developing AI-driven agents capable of handling key operational tasks, such as quoting, ordering, and coordination, autonomously. These systems act as digital collaborators that enhance team efficiency, enabling faster decision-making and freeing capacity for higher-value activities.

Microsoft Fabric as a Lakehouse

Fabric is becoming our analytics backbone: ingestion, processing, training, and monitoring of models unified under CI/CD practices. This ensures scalability, governance, and highly automated deployments.

Culture and Organizational Barriers Beyond the Algorithm

Success depends on technical sophistication and conquering cultural and organizational barriers:

- Skills gap: Hybrid talent, professionals who understand both aviation (MRO, regulations, logistics) and ML, remains scarce.

- Trust and explainability: Models must provide robust metrics, transparency, and stress-tested validation before moving into production.

- Change resistance: Operators and engineers, accustomed to traditional methods, may see AI as a threat or a “black box.”

- Hype vs. reality: Media buzz can create unrealistic expectations; meaningful adoption requires disciplined, incremental progress.

A Future of Self-Optimizing Aviation

If these barriers are overcome, aviation could operate as a self-optimizing system:

- Intelligent agents dynamically quote and optimize procurement costs while placing automatic orders.

- MRO systems autonomously reorder parts and schedule downtime with minimal disruption.

- Real-time executive dashboards show the immediate impact of every decision on revenue, costs, and emissions.

The future will belong to those who master scalable, efficient algorithms: trained on massive datasets, adapting in real time, leveraging distributed architectures, and optimizing hardware resources. As recent MIT studies suggest, blending computational efficiency with invariances, compression, and symmetries will be a true competitive edge.

Transforming Data into Automated Decisions Increases ROI

AI in aviation is far more than sleek dashboards. Rather, it represents a fundamental shift in how industry operations are conducted.

Adopting it requires more than “new technology.” It demands the right pipelines, culture, and talent to ensure models not only predict but act reliably and automatically, leveraging the scalability of technology.

Organizations already building strong data foundations, deploying models with engineering discipline, and experimenting with digital agents are achieving reduced costs, fewer failures, and improved customer satisfaction.

For leaders in aviation, the moment is now: transforming data into automated decisions is the advantage that will define the future of the industry.

BI Lead at AMP

With over 5 years of experience in the data industry, Miguel Guerra has built his career at the intersection of analytics and business transformation. He has successfully deployed more than 15 Machine Learning models across banking and aviation, translating advanced analytics into real financial and operational outcomes. An Economics and Business graduate and dedicated lecturer in Machine Learning, Deep Learning, Big Data, and Analytics, he is passionate about making data systems scalable and actionable. As a Business Intelligence Lead, he focuses on bridging analytics with business strategy to drive innovation and disruption in the aviation industry.

References

-

- Aviation Week. (2023, October 2). Optimizing Aerospace Supply Chain With AI and Big Data.

- Forest, F., Lacaille, J., Lebbah, M., & Azzag, H. (2018, December). Big Data Clustering with Spark for Engine Health Monitoring. IEEE International Conference on Big Data.

- MIT News. (2025, July 30). New Algorithms Enable Efficient Machine Learning with Symmetric Data.

- Sharma, S., Gupta, A., & Singh, R. (2024). Machine Learning Algorithms for Supply Chain Optimisation. International Journal of Supply Chain Management, 13(1), 22–35.

- Wang, J., Zhang, L., & Chen, Y. (2024). Generative Probabilistic Planning for Optimizing Supply Chain Networks. arXiv preprint arXiv:2404.07511.